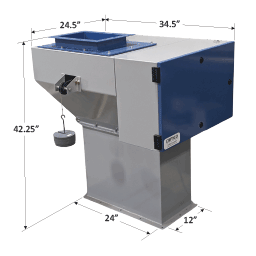

Dry Flow System – Precision Control for Dry Material Applications

In industries where the accurate flow of dry materials is essential to process quality and efficiency, Comco Controls provides a purpose-built solution: the Dry Flow System. Engineered for high-precision dosing, consistent throughput, and seamless system integration, this unit is ideal for a wide range of industrial applications, including feed manufacturing, grain processing, and material handling systems.

System Overview

The Dry Flow System is a smart, compact unit that provides:

- Continuous weighing of free-flowing dry materials

- Automated flow rate regulation via an electric-actuated discharge gate

- Integration-ready control platform with Ethernet connectivity and advanced sensor input

Whether you’re applying liquids to pelleted feed or conditioning grain with moisture, the Dry Flow System gives you tight process control with minimal operator intervention.

Key Benefits

High-Precision Flow Control

Real-time weighing and automated gate ensure consistent dry material flow.

Optimized for Dosing & Grain Conditioning

Enables accurate moisture control in tempering and conditioning systems.

Easy System Integration

Connects seamlessly with PLCs and SCADA via Ethernet and flexible I/O.

Low Maintenance & Simple Calibration

Designed for durability with easy on-site setup and minimal upkeep.

Key Features and Capabilities

- High-Accuracy Weighing: Utilizes LVDT technology to measure dry material mass in real time

- Controlled Discharge: Electric-actuated gate adjusts flow based on live weight feedback

- Integrated Moisture & Temperature Sensors: Enables optimized tempering and conditioning

- Wide Flow Range: Handles rates from 5 to 200 short tons per hour

- Manual or Automatic Operation: Configurable to suit production workflows

- Ethernet Connectivity: For integration with plant PLC or SCADA systems

- User-Friendly HMI: Includes local touchscreen and remote access options

- Flexible Liquid Controls: Supports up to two pump outputs, ideal for post-pellet oiling or pre-conditioning water dosing

- Simplified On-Site Calibration: Designed for easy setup and low maintenance

Applications

Feed & Grain Processing

Precision batching and flow regulation for optimal feed consistency.

Dosing & Tempering systems

Accurate dry material control in grain conditioning, tempering, and moisture-adjusted processing

Port-pelleting liquid application

Synchronizes flow control with additive application systems

bulk material handling

Enhances material throughput control for storage, transfer, or packaging operations