Feed Yard Automation, Engineering and Panels

Welcome to the forefront of feed automation, where innovation meets efficiency. Our comprehensive range of feeder automation and advanced process control solutions is tailored to elevate your cattle and livestock feeding operations. As a leading automation company, we specialize in providing cutting-edge automation solutions to meet the unique needs of the feed yard industry. Explore the possibilities of PLC automation and custom control panels designed to optimize every aspect of your feed yard.

Comco understands the challenges that feed yards face. This experience enables us to provide feature-rich feed automation solutions that are cost effective for any size operations.

Control Systems

- Full facility automation, front to back

- Comprehensive traceability and lot tracking

- Detailed searchable audits for all processes Extensive reporting capabilities

- Flexible import / export system

- Seamless integration with 3rd party applications

- Clear and concise custom graphics

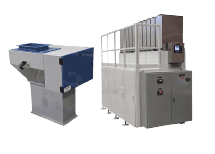

Specialty Equipment

- Easy-to-use, low maintenance Micro Ingredient Systems that is perfectly suited for large feedlots and dairies, yet economical for smaller producers as well.

- Accurate and robust Dry Flow Device to measure and regulate the flow of dry material to achieve optimal moisture content in feed.

- Water dosing stations to complement both systems above.

Receiving

- QA record keeping

- Cross-contamination prevention

- Unattended operations with automatic interfaces

- Custom equipment settings based on incoming product

- Toughpad integration

Mixing / Batching

- Advanced recipe management and material substitution

- Dynamic free fall calculation

- Merge or split orders

Cross-contamination prevention - Automated pre-weighed hand adds

- Customized loadout with feed truck system integration

Steam Flaking

- Full automation of steam chest and flaking mills

- Automatic or manual gap control

- Material flow rate and moisture content control

- Scheduled automatic warm up

- Trending charts for performance evaluation

- Automatic control of liquid applications